Call08045476106

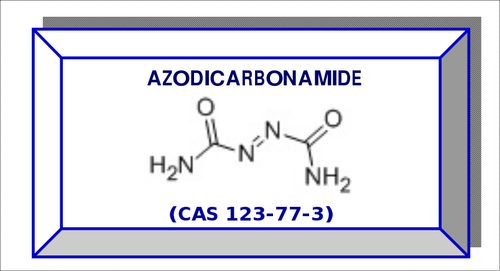

CAS-123-77-3 Azodicarbonamide

Product Details:

- Molecular Weight 116.08 g/mol

- Taste Tasteless

- HS Code 29270090

- Appearance Yellow powder

- Usage Used in the production of foamed plastics (PVC, EVA, PE), as a food additive in flour

- Application Blowing agent in plastics and rubber, flour bleaching agent

- Shelf Life 2 years

- Click to View more

X

CAS-123-77-3 Azodicarbonamide Price And Quantity

- 10 Kilograms

CAS-123-77-3 Azodicarbonamide Product Specifications

- Store in a cool, dry place, tightly sealed

- Odorless

- 200C (decomposes)

- Neutral

- Chemical

- 1.65 Gram per cubic centimeter(g/cm3)

- 123-77-3

- Powder

- 204-650-8

- Slightly soluble in water, insoluble in most organic solvents

- Powder

- Industrial Grade

- Orange yellow or yellow crystalline powder, odorless, decomposes at 200C

- Non-poisonous

- 99% Min

- C2H4N4O2

- Yellow powder

- Used in the production of foamed plastics (PVC, EVA, PE), as a food additive in flour

- 29270090

- 2 years

- Blowing agent in plastics and rubber, flour bleaching agent

- Tasteless

- 116.08 g/mol

CAS-123-77-3 Azodicarbonamide Trade Information

- 100 Kilograms Per Month

- 7-10 Days

Product Description

-

Azodicarbonamide CAS - 123-77-3

PROPERTIES AND USES

-

Easy Availability,

-

Superior Consistent Quality

-

Yellow To Orange Red Crystalline Powder,

-

Assay : 98.5 To 100.5 %%

-

Ph Of 2%% Aq Suspension > 5.0

-

Melting Point 224 To 227 Deg C

Packaging Details: 25 KG / 50 KG BAGS / DRUMS

-

Highly Efficient Blowing Agent for Plastics

Azodicarbonamide is extensively used in the plastics and rubber industries as a blowing agent. When heated, it decomposes and releases gases that create a uniform cellular structure, making it ideal for producing lightweight, foamed materials utilized in shoes, mats, and insulation. Its reliability and performance have made it a staple component for manufacturers seeking controlled cell formation and consistent foam quality in products.

Versatile Ingredient in the Food and Polymer Industries

While its primary use is in manufacturing foamed plastics, Azodicarbonamide also functions as a flour bleaching and dough conditioning agent in the food industry. Its dual-applicability showcases its versatility, meeting strict purity and stability requirements. When handled properly under recommended storage conditions, it maintains its effectiveness for up to two years, ensuring continuous production flow and product consistency.

Safe Handling and Storage Guidelines

Azodicarbonamide is a stable, non-poisonous powder under standard storage conditionscool, dry, and tightly sealed environments. Although it has excellent thermal stability up to its decomposition temperature, it is important to avoid roasting or heating above 200C outside controlled manufacturing processes. As it is not classified as hazardous or poisonous, handling it is straightforward, but always follow basic industrial hygiene practices for optimal safety.

FAQs of CAS-123-77-3 Azodicarbonamide:

Q: How is Azodicarbonamide typically used in manufacturing processes?

A: Azodicarbonamide is primarily used as a blowing agent in the production of foamed plastics such as PVC, EVA, and PE. It decomposes upon heating around 200C, releasing gases that help form cellular structures within the plastic, resulting in lightweight, insulating materials.Q: What benefits does Azodicarbonamide offer as a blowing agent?

A: The main benefit lies in its ability to decompose cleanly at a specific temperature, producing consistent gas evolution for uniform foam structures. This results in improved product quality, reduced material density, and enhanced insulation properties in finished plastics and rubbers.Q: When does Azodicarbonamide start to decompose during processing?

A: Azodicarbonamide starts to decompose at approximately 200C. At this temperature, it releases nitrogen, carbon monoxide, carbon dioxide, and ammonia gases, which contribute to the foaming process in plastic manufacturing.Q: Where is Azodicarbonamide commonly applied besides plastics?

A: Beyond plastics and rubber, Azodicarbonamide is occasionally used as a flour bleaching and dough conditioning agent in the food industry, helping improve flour quality and dough handling characteristics.Q: What safety considerations should be observed in handling and storage?

A: Store Azodicarbonamide in a cool, dry place with containers tightly sealed. Avoid exposure to heat above its decomposition temperature. Though it is not classified as hazardous for transport, adhering to standard industrial hygiene practices is advised for safety.Q: Is Azodicarbonamide classified as hazardous for transportation?

A: No, Azodicarbonamide is not considered hazardous for transport and does not have a UN number. It is also non-poisonous, odorless, and stable, making it straightforward to ship and handle under recommended storage conditions.Q: What is the typical shelf life and storage requirement for Azodicarbonamide?

A: The product remains stable and effective for two years when stored in a cool, dry, and tightly sealed environment, maintaining its properties and performance consistency throughout its shelf life.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email