Call08045476106

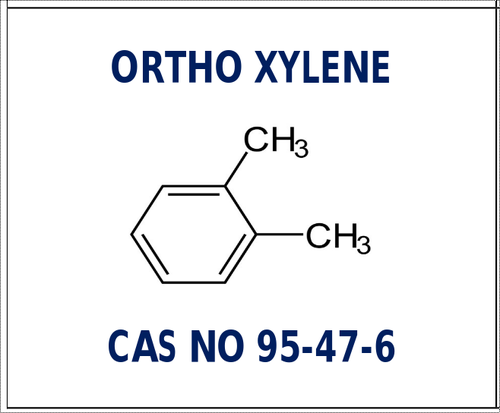

Cas-95-47-6 Ortho Xylene

Product Details:

- Molecular Weight 106.17 g/mol

- Appearance Clear, Colorless Liquid

- Solubility Insoluble in Water, Soluble in Organic Solvents

- Ph Level Neutral

- Density 0.88 Gram per cubic centimeter(g/cm3)

- Storage Instructions Store in Cool, Well-Ventilated Area, Away from Sources of Ignition

- Odour Sweet, Aromatic

- Click to View more

X

Cas-95-47-6 Ortho Xylene Product Specifications

- Petroleum Derived

- Paints and Coatings, Solvent, Chemical Intermediates

- Clear, Colorless Liquid

- Industrial Chemical

- Store in Cool, Well-Ventilated Area, Away from Sources of Ignition

- 99% min

- Sweet, Aromatic

- 106.17 g/mol

- Direct Use, Blending, Dilution

- Insoluble in Water, Soluble in Organic Solvents

- 2 Years from Manufacturing Date

- Liquid

- 24 Months

- Industrial Solvent, Intermediate for Phthalic Anhydride Production

- 0.88 Gram per cubic centimeter(g/cm3)

- Ortho Xylene

- 1,2-Dimethylbenzene; o-Xylene

- Aromatic Hydrocarbon

- 95-47-6

- Neutral

- Rapid Evaporation

Product Description

The synthesis of N, N-dimethyl-5-cholest-3-ene-5-acetamide may be carried out using ORTHO XYLENE (CAS-95-47-6). The production of ORTHO XYLENE (CAS-95-47-6), a significant petrochemical, involves both coal carbonization in the production of coke fuel and catalytic reforming. In addition to being employed as a solvent, o-Xylene is a crucial precursor of phthalic anhydride. It is a component in the creation of terephthalic and isophthalic acids. Additionally, it serves as a solvent in the production of rubber, paint, varnish, glue, and printing ink.

Superior Solvent Performance

Ortho Xylene demonstrates high solvent power and rapid evaporation, making it ideal for use in paints, coatings, and chemical blending processes. Its clarity and consistent purity contribute to improved finishes and enhanced process efficiency in industrial applications.

Safe Handling and Storage

Classified as a Flammable Liquid (Hazard Class 3, UN Number 1307), o-Xylene requires careful handling. Users should employ protective equipment, avoid inhalation, and ensure storage in cool, well-ventilated areas away from ignition sources, minimizing risks during transportation and use.

Versatile Industrial Applications

From acting as a raw material in phthalic anhydride manufacture to functioning as an effective solvent in the paint and coatings sector, Ortho Xylenes versatility supports numerous chemical processes. Its compliance with global regulatory standards ensures it meets diverse industry requirements.

FAQs of Cas-95-47-6 Ortho Xylene:

Q: What is the primary usage of Ortho Xylene in industrial applications?

A: Ortho Xylene is mainly used as an industrial solvent and a chemical intermediate, particularly for the production of phthalic anhydride. It is also widely utilized in the paints and coatings sector for its excellent solubility and rapid drying properties.Q: How should Ortho Xylene be stored to ensure stability and safety?

A: To maintain stability and safety, Ortho Xylene should be stored in cool, well-ventilated areas, away from sources of ignition. It must be kept in sealed steel drums or bulk tankers, and handled using appropriate protective equipment to prevent exposure and fire risks.Q: When is Ortho Xylene considered expired or unsuitable for use?

A: Ortho Xylene is best used within 2 years from its manufacturing date. While it remains stable under recommended storage conditions, using it beyond its shelf life of 24 months or if packaging is compromised may reduce its effectiveness and safety.Q: What environmental considerations are associated with the use of Ortho Xylene?

A: Ortho Xylene is harmful to aquatic life and should not be released into the environment. Proper containment, adherence to waste disposal regulations, and prevention of spills are necessary to mitigate environmental impact during its use and handling.Q: Where can Ortho Xylene be applied directly, and what are its benefits in these processes?

A: Ortho Xylene can be applied directly in chemical manufacturing, paint formulation, and solvent blending. Its benefits include high solvent efficiency, rapid evaporation for faster drying, and consistent purity that enhances end-product quality.Q: How is Ortho Xylene regulated and what standards does it meet?

A: Ortho Xylene complies with major regulatory frameworks such as TSCA in the USA and REACH in Europe. It is classified as a Flammable Liquid (Class 3) and carries the UN Number 1307, ensuring safe transportation and usage standards in industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email